- About

- Products

- Solutions

- Partners

- Resources

- Projects

- Installation

- News

- Contact Us

info@b-panel.com | +62-22 686 7077

info@b-panel.com | +62-22 686 7077

Abstract

One factor that determine the strength of the building structure is dead load of the building itself. Weight of the building is determined by the mass of structural loads (columns, beams, and slabs) and non-structural loads (walls and roof) of the building. More mass of a building, it will be more stable, sturdily standing and difficult to collapse. However, the carrying capacity of supporting building must also be large and will eventually also affect the cost. In fact, we can establish a solid building with a minimal burden of building, especially for non-structural components not contributing to the strength of building structure, as its mass is of no use.

Other than that, in structural dynamics we know about pendulum effect. Pendulum effect occurs when there is a force from outside the structure which pressing the structure, for example, wind forces or earthquake forces. More weight mass of structure, the pendulum effect would be even greater, and will be greater the risk of building collapse. Compare if the burden of building is light, surely the risk of its collapse would be even smaller. b-panel® provides a solution to ease the weight of building, but still produce a solid structure, sturdy stand and resistant to earthquakes.

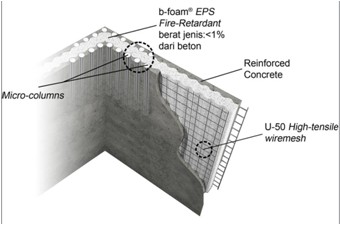

b-panel® is a building system that is composed of b-foam® Expanded Polystyrene (EPS), wiremesh (as reinforcement), and the cast concrete. EPS is not a strong material, but its function in b-panel® system as a permanent formwork (buried). The result is a reinforced concrete material that is lightweight but very strong compared to their weight (excellent strength to weight ratio) and of course can be used as a material constituent of civil buildings. Once construction is complete, this EPS layer also serves as an insulation temperature (isotherm) and sound (isoacoustic) which is very good.

As shown in figure, the main constituent material b-panel┬« is b-foam┬« EPS. b-foam┬« makes the b-panel┬« becomes lighter than other materials because of the density of b-foam┬« which used is around 10 – 24 kg/m3 (1/200 the density of concrete). Then what about the density of b-panel┬« itself after b-foam┬« EPS is combined with steel wiremesh and cast concrete? And how if it is made into the material for building construction? What about other materials?

Here we will clarify the comparison of b-panel® with other material for building construction (as example for material which making up the wall):

- eng.jpg)

Seen in the graph in terms of its constituent material, used of b-panel® is lighter than other materials. The thicker the walls of the building, b-panel® will be much lighter than other materials, because the addition of material is only affected by the addition of b-foam® EPS thickness which density is very light. Because of that weight, increase with b-panel® for the greater wall thickness is very small.

Weight ratio of material above is compare dry weight of a material. In reality, material for construction building can not be 100% dry. One main cause is due to the rain. Indonesia is located in tropical climate with high rainfall and high relative humidity.

Water becomes main factor in increasing the weight of material, because the water seeps into the material. This makes the material expands and become more weight because the water which is absorbed into material also has weight. Penetrating power of water in a material depends on the density of the material itself. If water has entered it will be difficult and took quite a long time to come out again (Example: in water absorption test, a specimen of conventional brick and light weight brick should be inserted into oven to get the material dry completely). Here is described the amount of water absorption for each type of material:

- eng.jpg)

For lightweight brick (AAC) will be used more accurate calculation, based on the relative humidity in Indonesia:

.jpg)

The average relative humidity in Indonesia in the morning reached 95%. With interpolation calculation, the increase weight of lightweight brick in saturated condition is 113.1 kg/m3 .

.jpg)

Striking differences occur in ÔÇťbatakoÔÇŁ material, water seep greatly affect the increase of ÔÇťbatako’sÔÇŁ weight. Because the density of ÔÇťbatakoÔÇŁ is very distant, it makes almost 50% of water absorbed into it.

The increment is quite noticeable also seen in the conventional brick material, concrete stone, and even lightweight brick. All type of material show significant increase in weight after saturated condition. Conventional brick and lightweight brick material, showed increase in weight reaches 20%. Imagine if the thickness of wall become thicker, it would be very influential at all. So it’s not guarantee lightweight material will be always be lighter, it’s proven when the thickness was increased.

While for b-panel® material the increment in volume is relatively small. Even for the increment thickness and in the long run though, b-panel® material still showing little change and relatively stable, rising only 1% weight of material, because EPS does not absorb water. Unlike the other material, when the wall gets thicker it will be more extreme increment weight of material. This is the advantage of b-panel®, especially when the wall thickness is increasing, it can even be much lighter than lightweight brick material.

Besides adding weight, water absorption also worsen the performance of heat insulation on the walls. This is because water is a good conductor of heat. In addition, the presence of water which seeped into the walls can also make indoor air quality become worse, due to high humidity. The worst impact, mold and mildew can be bred.

It has been shown that b-panel® has a relatively light weight and stable for increasing thickness. It is proved from the constituent material only, and has more superior to the other constituent material. Initially lightweight brick is mild, especially for thin-walled, lighter than b-panel® but after the wall thickness increases, the addition of weight will be exceed b-panel® (shown in the chart that, at wall thickness reached 12 cm lightweight brick has begun to be more heavy).

To be more explicit let us try to compare the constituent material of conventional brick, lightweight brick with b-panel® for the design of 3-storey building houses in the following below:

.jpg)

Calculation of Building Dead Load

Concrete Gravity = 2400 kg/m3

Conventional Brick Gravity (installed + plastered) = 1.700 kg/m3

Lightweight Brick Gravity (installed + plastered) = 780 kg/m3

Volume of Wall = 233 m2

Area = 160 m2

Volume of beam = 0,3 m3

Volume of column = 0,8 m3

Weight Calculation: 3rd Floor

Dead Load

Weight of Slab (konvensional) = 0 kg

Weight of Wall (conventional brick) = 233 m2 x 255 kg/m2 = 59.415 kg

Weight of Wall (lightweight brick) = 233m2 x 117 kg/m2 = 27.261 kg

Total Weight 3rd Floor(b-panel®) = 49.143 kg

Total Weight 3rd Floor (conventional brick) = 82.695 kg

Total Weight 3rd Floor (lightweight brick) = 50.541 kg

Volume of Wall = 303 m2

Area = 180 m2

Volume of beam = 4,4 m3

Volume of column = 2,5 m3

Weight Calculation: 2nd Floor

Dead Load

Weight of Slab (conventional) = 180 m2 x 288 kg/m2 = 51.840 kg

Weight of Wall (conventional brick) = 303 m2 x 255 kg/m2 = 77.265 kg

Weight of Wall (lightweight brick) = 303 m2 x 117 kg/m2 = 35.451 kg

Total Weight 2nd Floor(b-panel®) = 115.173 kg

Total Weight 2nd Floor (conventional brick) = 168.885

Total Weight 2nd Floor (lightweight brick) = 127.071 kg

Volume of Wall = 235 m2

Area = 204 m2

Volume of beam = 5,8 m3

Volume of column = 3 m3

Weight Calculation: 2nd Floor

Dead Load

Weight of Slab (conventional) = 204 m2 x 288 kg/m2 = 58.752 kg

Weight of Wall (conventional brick) = 235 m2 x 255 kg/m2 = 59.925 kg

Weight of Wall (lightweight brick) = 235 m2 x 117 kg/m2 = 27.495 kg

Total Weight 1st Floor(b-panel®) = 120.849 kg

Total Weight 1st Floor (conventional brick) = 166.113

Total Weight 1st Floor (lightweight brick) = 133.683 kg

Total Weight floor 1,2,3 (b-panel®) = 285.165 kg

Total Weight floor 1,2,3 (conventional brick) = 417.693 kg

Total Weight floor 1,2,3 (lightweight brick) = 311.295 kg

Using b-panel® in the building significantly reduces total weight vs. using the other materials, 32% lighter weight than conventional brick and 8% lighter than lightweight brick.

b-panel® can actually decrease the weight of building. Especially when compared with conventional bricks, the material which always used daily by most people even until now, it has very significant weight reduction. More importantly, weight building reduction by b-panel® material accompanied by monocoqueb-panel® feature, where the whole building is one unit (the whole wall is load bearing system) makes it so much safer in the event of an earthquake. This factor also makes the total weight of the building with the b-panel® lighter than even lightweight brick, whereas lightweight brick only serves as a filler alone without support load of the building, while b-panel® despite its low weight, it is able to efficiently support the building

.jpg)

So, do you still want to pile up bricks just to add the weight to the building ?